HIGHEST QUALITY SINCE 1986

Moultrie Tool & Manufacturing is a tool and die shop specializing in dies, automated machines, specialized machines and custom gages and inspection tools. We are devoted to the highest quality and safety standards in the products and services we provide.

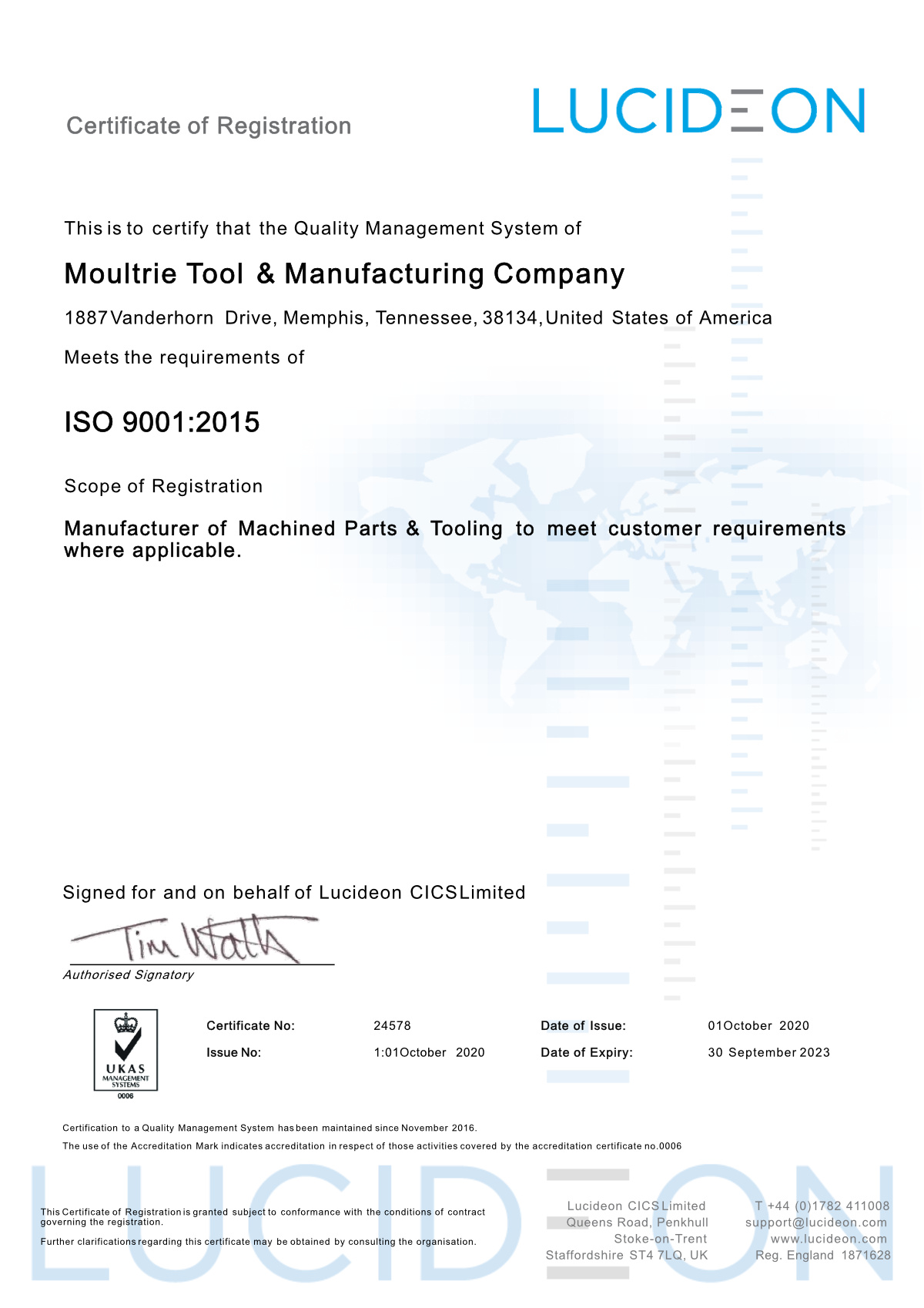

We were founded in 1986 by Lyndell Moultrie whose intention was to provide the highest quality machines, components and services to companies throughout the United States as well as the small job shop around-the-corner. In 2007 we became a certified ISO facility.

To this day, that is exactly what Moultrie Tool & Manufacturing has done and will continue to do. No job is too great nor small for us to tackle. We hope this glance at our company will show you why Moultrie Tool should be your first choice for your next tooling, machining, automation, quality control or engineering project.

ISO 9001 Certification

Proven Track Record

SAM.gov Registered

Highest Safety Standards

PRODUCTS & SERVICES

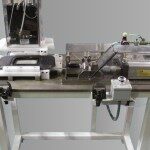

Moultrie tool has a proven track record of providing state-of-the-art special machines to numerous aspects of the manufacturing industry. From the automotive industry to the medical industry and all in between, our custom made machines, fixtures and inspection equipment can be found performing under the harshest of conditions. These machines and fixtures are specifically designed and built to our customer’s exact needs and specifications.

We offer an array of services in the fields of mechanical and industrial engineering that include:

Component Assembly

Component assembly machines with packaging capabilities if desired.

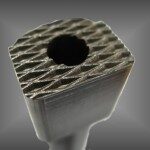

Production Machining

Production machining centers which can perform drill, tap, face, counterbore, mill, rout and other machining and forming functions on a high-speed large volume basis.

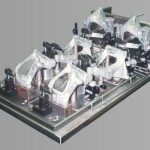

Custom Gauges

Precision custom gauges, inspection tools & high speed Quality Control inspection machinery.

Machine Fixtures

Machine Fixtures, assembly fixtures & inspection fixtures. Progressive dies, trim, coining & forming dies.

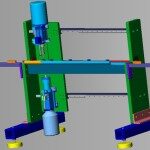

Solid Modeling

Solid Modeling of machines & components, Computer Aided Manufacturing services, part/component inspection with traceability to N.I.S.T. Field engineering services for machinery & production line equipment.

Prototype Development

Prototype development, design and manufacturing of prototype parts and components.

EQUIPMENT & TECHNOLOGY

In the industrial market today, staying up-to-date with technology advances can be time consuming and expensive. To save plant engineers and designers this time and expense, Moultrie Tool gathers information from a database of hundreds of trusted industrial, electrical & electronic suppliers and implements the latest technology available on the machines and tools we provide.

Our 14,000+ square foot plant is fully air conditioned to ensure stability & integrity of the machines we use to manufacture parts and components.

Moultrie Tool relies on Solid Works for solid model designs of the tools and equipment we manufacture. A detailed Bill of Material is generated automatically with the Solid Works system which can be exported to a database program such as Microsoft Excel to pass on to designers and purchasing agents. In conjunction with Solid Works software, we utilize Mastercam for programming our CNC equipment.

DETAILED LIST OF MACHINERY

Quality Control

Browne and Sharpe Coordinate Measuring Machine, MicroVu Optical Comparitor with Printer, Federal .00005 DimensionAir Gauge and Air Gauges, Clark Hardness Tester, Multiple Granite Surface Plates, gauge Block Sets, Pin Gauges, Precision Hand Measuring Instruments, Height Gauges, Master Height Gauges

Milling Machines and Accessories

3 Lagun Vertical Turrett Milling Machines with 2 Axis Anilam Readouts, 2 Bridgeport Vertical Turrett Milling Machines with 2 Axis Anilam Readouts, Bridgeport E-Z Trak CNC Milling Machine with .0001 Digital Readouts, Fadal 40-20 CNC Milling Machine with 4th Axis, Atlantic Jig Borer, 1 Pilgrim Vertical Turrett Milling Machine with 2 Axis Anilam Readouts, Multiple Boring Heads, Indexes and Rotary Tables, Numerous Vices and Collet Sets

EDM Equipment

2 Fanuc Robocut Water Submerged EDM Machine, Agie Elox Submerged Sinker/Graphite EDM.

Welding and Heat Treatment

Cress Heat Treat Furnace, Clark Rockwell Tester, 2 Hobart Wire Welders, ESAB L-TEC TIG and Arc Welder, Gas Torch

Drill Presses and Punch Presses

Solid Summit #3XHD Drill Press, American 4′ Radial Arm Drill Press, 1 Powermatic Drill Presses, Bux & Milwaukee Portable Magnetic Drills, 3 Hydraulic Presses, 45 – 30 – & 10 Ton Punch Presses

Lathes and Accessories

Hyundai CNC Lathe with SpaceSaver Bar Feeder, Monarch 10 EE Precision Lathe, Republic Lagun High Speed Precision Lathe 16 x 60 with Readouts, Colchester Mascot 1600 Lathe with Acu-Rite Readouts, Hardinge Finishing Lathe, Various Chucks and Boring Tools, Milltronics CNC Tool Room Lathe w/ Turret

Grinders, Saws and Sanders

Chevalier Wet Grinders FSG-618 6″ X 18″, 1 Chevalier Hydraulic Wet Grinder 6″ X 18″, 1 Okamoto Hydraulic Wet Grinder 12″ X 24″, 1 Brown & Sharpe Hydraulic Wet Grinder 12″ X 24″, 1 Brown & Sharpe OD – ID Grinder, 1 Fuji OD – ID Grinder, Numerous Diamond and CBN Wheels, 1 Covel #10 Surface Grinder, 1 Sunnen Honing Machine, End Mill, Tap & Cutter Sharpeners, 1 Dedtru Grinder Machine, Bench Grinders Sanders and Finishing Equipment, 1 Doall Vertical Bandsaw, 3 Horizontal bandsaws, Greenlee Portable Power Bandsaw, 1 Power Chopsaw, Yuasa Jig Grinder 80,000 RPM, Kellenberger 10000 OD/ID Face Grinder, Sandblasting Cabinet and Equipment, Medina 42″ End Grinder

Miscellaneous Shop and Office Equipment

(3) 2 Ton Hoists, 7.5 HP Air Compressor, (2) 15 HP Air Compressors, 16′ Flatbed Chevrolet Truck, 3/4 Ton Truck, 10,000 # Tandem Axle Trailer, 8,000 # Forklift, 12,000 # Forklift, 3,000 # Forklift, 3 Die Carts, Hydraulic Presses, Arbor Presses, Solidworks 2007 Office Professional, Mastercam Wire, Mastercam Lathe, 2 Seats of Mastercam Mill, Plotter and Printers For Various Computer Systems, Various Power Hand Tools Such As Drills, Die Grinders, Sanders, Etc., 14,000 Square Feet Of Office And Climate Controlled Shop Floorspace, 4 Steel Racks, Various Electrical And Air Fittings And Supplies On Hand

PRODUCT TOUR

ISO CERTIFICATION

HIGHEST QUALITY AND SAFETY STANDARDS

Big or small, we’ve got a quality solution when you need it. We provide the highest quality machines, components and services. Moultrie Tool should be your first choice for your next tooling, machining, automation, quality control or engineering project. Contact us for your next project…

CONTACT US

1887 VANDERHORN DRIVE

MEMPHIS, TENNESSEE 38134

PHONE (901) 383-1913

FAX (901) 383-1953

EMAIL: QUOTE REQUESTS, PRINTS, IMAGES OR GENERAL INFORMATION – INFO@MOULTRIETOOL.COM

EMAIL: OFFICE / ACCOUNTING – LAURIE@MOULTRIETOOL.COM

EMAIL: SALES / ENGINEERING – LANE@MOULTRIETOOL.COM

WWW.MOULTRIETOOL.COM